End Mills -Number of Flutes - Center-Cutting End Mills | YCK2020

Dao phay ngón là dụng cụ cắt dọt đa dụng và hoạt động rất hiệu quả trên các máy công cụ. Với những trung tâm gia công CNC kiểu đứng hay nằm ngang nó đều được sử dụng rộng rãi.

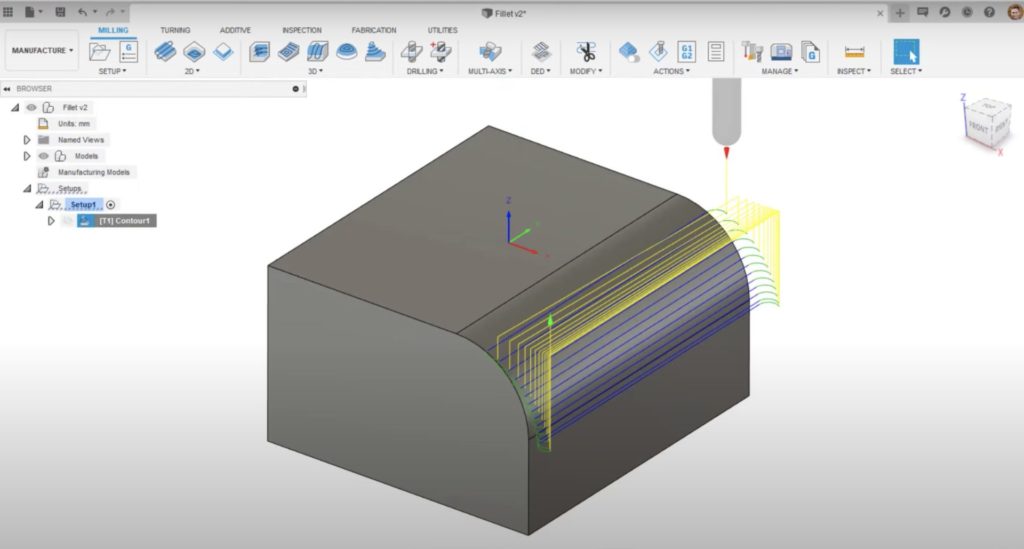

Đây là dạng mề mặt chi tiết có thể gia công được bằng dao Phay ngón .

Bài viết này giới thiệu về một số loại dao Phay ngón thông dụng.

Phân loại dao phay ngón

Và đặc điểm của dao phay ngón thường dùng trong các máy Phay CNC.

Tags: Center-Cutting End Mills, Number of Flutes, End Mills,

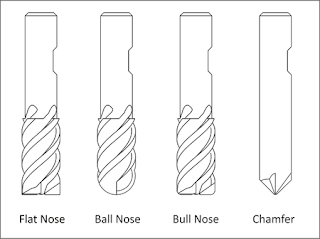

Milling tools include flat, ball, bull nose and chamfer.

|

|

Figure 3.1: Mill Tool Nose Types |

Flat nose mills are used for milling 2D contours and pockets. Ball

nose mills are used for 3D milling. Bull nose end mills have a radius corner.

They are used to create a fillet on the bottom of a wall. Because they are

sturdier than an end mill they are also sometimes used for roughing operations.

Chamfer mills have an angled nose used to create a chamfer or to de-burr parts.

Number of Flutes

Milling tools usually have either two or four cutting flutes. Two

flute cutters provide more chip clearance when milling in close areas. Four

flute mills are more rigid, can be fed faster, and are preferred when greater

chip clearance is not required, such as when milling an outside contour.

Center-Cutting

End Mills

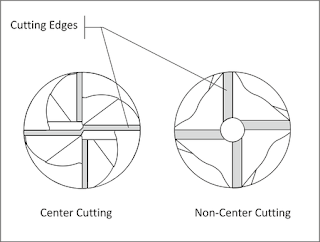

Milling tools are either center cutting or non-center cutting.

Center cutting mills can plunge straight down into material, while non-center

cutting tools cannot.

Figure 3.2 below shows the cutting end view of a center cutting

and non-center cutting end mill. Notice that the cutting edges of the center

cutting end mill continues to the center of the tool. The center of the other

has a small hole at the center. Non-center cutting end mills require a pilot

hole, ramping or helical motion to plunge into material.

Figure 3.2: End View of Center and Non-Center Cutting End Mill |

Có thể bạn quan tâm: