Tốc độ cắt gọt (Cutting speess) và bước tiến (Feeds) là những thông số quan trọng của quá trình cắt gọt kim loại.

Những thông số này sẽ giúp ta chọn chế độ cắt gọt tối ưu trên các máy công cụ cắt gọt kim loại, kể cả các máy công cụ điều khiển số CNC..Nó rất quan trọng trong ngành gia công cơ khí chĩnh xác.

Đây là những công thức giúp ta có được lựa chọn tối ưu chế độc cắt gọt.

Nguồn tham khảo từ WWW.Cimco.com

Mọi người cũng tìm kiếm: Cutting Speeds and Feeds Formulas, Cutting Data, CAD/CAM, Dao Phay Dinh Hinh, Drill Cycles Speed Data, công nghệ chế tạo máy, Cutting Feeds, chế tạo máy, Hướng dẫn vẽ 3D,

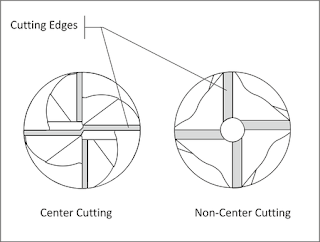

The tool moves through

the material at a specified rotational speed, defined in revolutions per minute

(RPM), and feed rate, defined in inches per minute (IPM). Probably the most

vexing problem for the beginning CNC machinist is selecting proper cutting

speeds and feeds. This selection is actually more difficult on a CNC than a

manual mill because, with a manual mill, the operator can feel the cutting

pressure and alter the feed based in part on the cutting force.

CNC mills require

calculating speeds and feeds in advance. These speeds and feeds can, and often

are, adjusted at the machine based on chip shape and color, cutting sound, and

machine horsepower meter readings.

The best source of data

about cutting speeds and feeds for a specific tool, application, and material

is the tool supplier. Much of this data is found on manufacturer's web sites or

printed tooling catalogs. Tool sales representatives can be a valuable

resource, so if you do a lot of machining, develop a good relationship with a

knowledgeable representative.

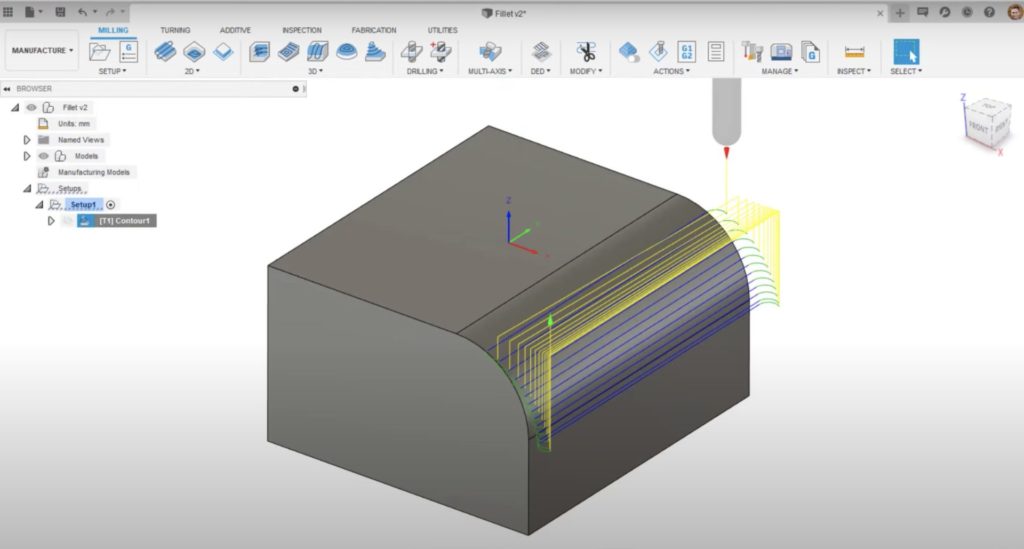

Another source of speeds

and feeds data is CAD/CAM software. These have become increasingly

sophisticated and often provide good cutting data.

Yet even the best speed

and feed data is just a starting point. Speeds and feeds require adjustment due

to many factors including the maximum spindle speed or horsepower of the

machine, rigidity of work holding, and the quality and condition of the machine

tool itself.

The following pages

provide cutting data for the most commonly machined materials and a methodology

for calculating speeds and feeds. As always, use common sense. If the part is

held by double sided tape, feeds based on vise work holding are probably too

high. If the tool is very long and thin, speeds and feeds will likely require

reduction.

Speed Formula

Milling machine cutting

speeds are derived from the following formula:

|

| Figure 3.14: Speed Formula |

|

Speed is the rotational

frequency of the tool (Spindle Speed) in revolutions per minute (RPM).

SFM (Surface Feet per

Minute) is the speed at which the material moves past the cutting edge (outside

diameter) of the tool in feet per minute. SFM values depend on the tool type,

tool material, and material being machined.

Circumference is the

circumference of the cutting tool in feet.

How Speed Formula is

Derived

Because cutting tools

are defined by their diameter in inches, this formula is rewritten and

simplified as follows:

|

|

|

Figure

3.15: Speed Formula (Simplified)

|

Dia is the tool diameter

in inches.

3.82 is a constant

derived from 12/pi which converts the tool circumference in feet to diameter in

inches.

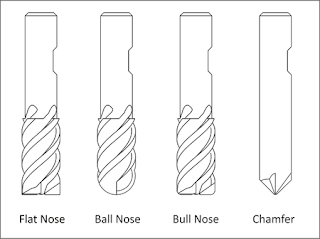

Cutting feeds are in IPM

and use the following formula:

|

Figure 3.16: Feed Formula

|

Feed is the linear feed

of the tool through the material in inches per minute.

Speed is the result of

the speed formula (Figure 3.15) in revolutions per minute.

CL is the chip load, or

how much material each cutting edge of the tool removes per revolution. Chip

load is sometimes referred to as feed per tooth (FPT) or inches per rev (IPR).

NumFlutes is the number

of cutting flutes. (For a twist drill, this value is one.)

Tap Feed Formula

For tapping operations,

feed rate is based on the number of threads per inch and feed rate:

|

|

|

Figure

3.17: Tap Feed Formula

|

Feed is the linear feed

of the tool through the material in inches per minute.

Speed is the result of

the speed formula (Figure 3.15) in revolutions per minute.

TPI is the threads per

inch of the tap. For example the TPI of a 1/4-20 tap is 20.