Hole-Making Tools | YCK2020

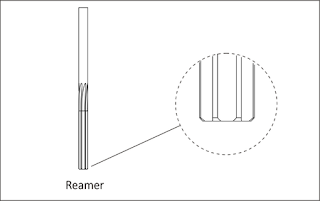

Center-Spot Drills

Center (spotting) drills

are short and very rigid drills used to create a conic on the face of the part.

Because they come to a sharp point and resist bending, they locate the hole

precisely. The conic helps prevent the subsequent drill from wobbling and

ensure the drill is located precisely and drills straight down.

Countersink drills are

used to create the conical face for a machine screw. Combined

spotting-countersinks are used to create a screw clearance hole and countersink

in one operation.

There are many different

sizes and tip angles of center, countersink, and combined drills. Be sure the

tip angle of the countersink matches the included angle of the machine screw,

and that the drill diameter is greater than the screw head diameter.

|

|

Figure 3.6: Countersink and Center Drill |

Twist Drill

Twist drills are

available in many diameters and lengths. Usually made of high speed steel,

carbide, or cobalt, they may also be coated with titanium nitride (TiN) for

longer life. The tip angle of most twist drills is 118 degrees.

|

|

Figure 3.7: Twist Drill |

Taps

Cutting taps form

threads by shearing material away. Form taps (roll taps) form the thread by

forming the metal to shape. Form taps produce no chips and are used for soft

materials including aluminum, copper, brass and plastics.

|

|

|

Figure

3.8: Taps |

Bottoming taps are used

to tap blind holes. Spiral point taps push the chip ahead and out the bottom of

a through hole.

Taps require a hole

drilled to the correct size to ensure the thread is formed properly. For

example, a ¼-20 cutting tap requires drilling a .201 (#7) hole. Refer to the

drill chart in Appendix F to find the correct drill size for

a specified thread size and fit.

Most CNC Machines

support rigid tapping, which means the tap can be held in a rigid holder. The

tap is advanced at a feed rate that matches the thread lead into the hole. The

spindle then stops, reverses, and backs out of the hole.

Machines without rigid

tapping require special tapping attachments. Always refer to the manufacturers'

instructions as the speed, feed, and other machining parameters for tapping

attachments may be different that those for rigid tapping.

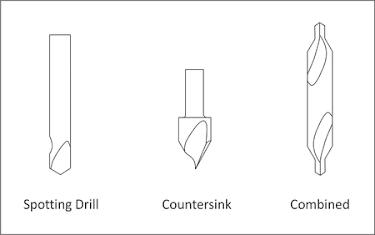

Reamer

Use reamers to create

holes of precise shape and excellent surface finish. Reamed holes are usually

accurate within .0002 inches diameter. For example, a reamer is used for holes

used for ground pins and bushings.

Reamers require a

specific size hole be drilled before use. Cutting speeds and feeds are also

important. Remove too little or too much material and the hole will not be the

correct size.

|

Figure 3.9: Reamer |

Counterbore

A counterbore looks

similar to an end mill with a pilot in the center. It is used to spot face

holes and the pilot ensures the spot face is centered on the hole.

Counterboring is not

necessary when using a CNC machine. Rather, create a spot face using a pocket

or circle mill tool path. This saves having to buy and stock counterbore tools

and pilots, and the time required to load and set up the counterbore.

See more:

- Simulation

- SINUMERIK 808D Tutorial Milling

- Slot Mill / Slotting Saw

- Speed/Feed Examples

- Thiết kế phôi

- Thiết kế Trục bậc

- Tool wear

Không có nhận xét nào:

Đăng nhận xét

Nội dung bài viết này có hữu ích với bạn không? #YCK2020 - Dự án Hỗ trợ Cộng đồng Cơ khí Trẻ